Vacuum gripping Type

Pillow block bearing is a bearing unit which combine olling bearing and housing together.Most of the outer spherical bearings are made of the diameter sphere,and with a ball bearing inner hole are arranged together,various structure form-kind,good versatility and interchange ability.Pillow block bearing is a bearing unit which combine olling bearing and housing together.Most of the outer spherical bearings are made of the diameter sphere,and with a ball bearing inner hole are arranged together.

Inquiry Now

add to cart

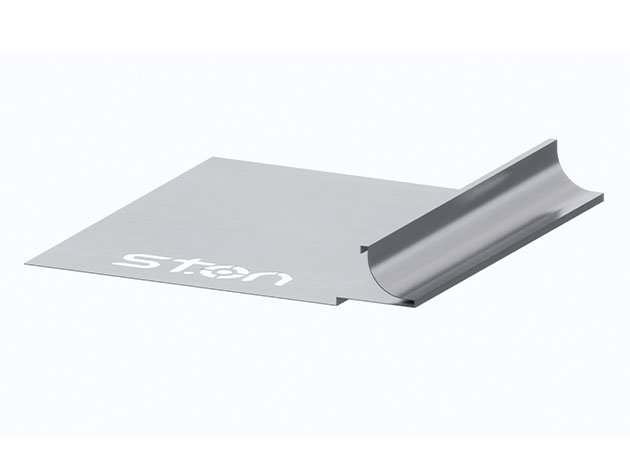

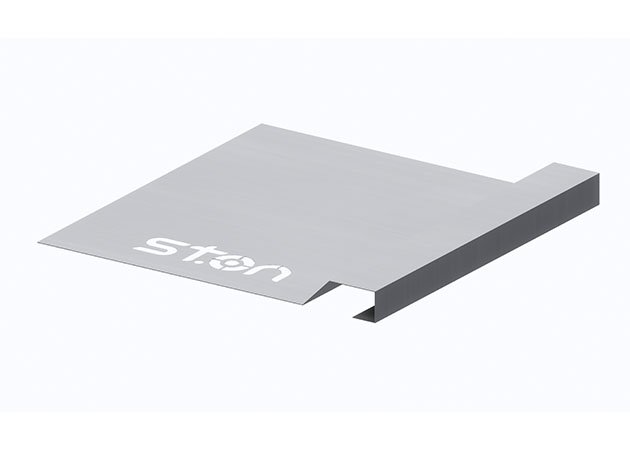

··· Panel Bender-Vacuum Gripping Type ···

Model:STON A1,B1

Max Bending Length:1000~1400mm

STON-A1 | STON-B1 | |

Dimension(L×W×H) | 2800×1500×2800 | 3400×2000×2800 |

Feeding method | Vacuum Gripping | Vacuum Gripping |

Max. bending speed | 0.2s/knife | 0.2s/knife |

Max. bending length (mm) | 1000×1000 | 1400×1250 |

Max. bending height(mm) | 170 | 170 |

Min bending thickness(mm) | 0.15 | 0.15 |

Min. four-sided forming size(mm) | 140×140 | 160×190 |

Single-sided forming | 140mm | 160mm |

Max.bending thickness(mm) | stainless steel 1.2 Steel plate 2.0 Aluminum plate 2.5 | stainless steel 1.5 Steel plate 2.5 Aluminum plate 3.0 |

Overview

The STON Panel Bender is equipped with a vacuum gripping system that automatically holds and feeds sheet materials, making it especially suitable for smaller and light-duty workpieces. The system ensures precise positioning and stability during bending, minimizing manual intervention and improving efficiency, making it an ideal choice for light-duty bending tasks.

Learn more

Bending Demonstrations

Industry Applieation Cases

-

STON Sample

STON Samplewatch the process

-

Refrigerator Component

Refrigerator Componentwatch the process

-

EV Charging Station Cover Plate

EV Charging Station Cover Platewatch the process

-

Livestock Machinery Component

Livestock Machinery Componentwatch the process

Case Show

-

BBQ grill

BBQ grill -

Building curtain wall

Building curtain wall -

Kitchen workbench

Kitchen workbench -

Reefer truck box

Reefer truck box -

Air conditioner

Air conditioner -

Elevator

Elevator -

Filing cabinet

Filing cabinet -

Vending machine

Vending machine

··· check your industry match ···

Component Introduction

-

01.

Material Compatibility

The STON Panel Bender is compatible with a wide range of materials, including stainless steel, steel plates, and aluminum alloy plates. The equipment maintains consistent bending accuracy and surface quality when processing different materials, meeting the demands of various application scenarios.

-

02.

Structural Design and Castings

The STON panel bender features a high-strength cast iron structure, treated with high-temperature annealing and precise machining to enhance rigidity. This design minimizes long-term operational errors, ensuring stability, precision, and extended service life.

-

03.

Motor and Drive System

The STON Panel Bender uniquely employs same-brand high-performance servo absolute motors and drive systems, ensuring seamless coordination between components. The absolute motors provide precise positioning without resetting, maintaining accuracy. This system handles multi-axis coordination and complex tasks, boosting production efficiency and minimizing downtime.

-

04.

Vacuum Gripping

The vacuum gripping system of the STON Panel Bender uses multi-point suction to securely grip various sheet sizes, ensuring precise positioning. The system adjusts pressure dynamically to prevent deformation and slippage across different materials.

-

05.

Control System and Interface

The STON Panel Bender is equipped with an intelligent control system and an intuitive user interface. It supports up to 100,000 3D models, offers multi-language programming, real-time monitoring, and remote diagnostics. Users can easily adjust production parameters, optimize bending paths, and reduce manual intervention, ensuring the smooth execution of complex bending tasks.

-

06.

Bending Tools

The STON Panel Bender is equipped with high-strength, wear-resistant, and versatile bending tools, suitable for processing a variety of materials. The tool heads are made from premium high-strength steel, precision-engineered for exceptional durability. The flexible tool design allows for quick changes to accommodate different processing requirements, ensuring optimal performance across a range of applications.

-

07.

Auxiliary and Automatic Tooling Technology

The STON Panel Bender integrates auxiliary and automatic tooling technology. Auxiliary tools enable the completion of multiple tasks in complex processes without changing primary tools. The automatic tooling technology configures tool combinations via a CNC system, reducing setup time, making it particularly suitable for production lines.

-

08.

Electrical System

The STON Panel Bender’s electrical system is meticulously designed with high-quality electronic components that meet international standards, ensuring stable power supply and signal transmission. The electrical system includes overload protection and intelligent fault detection, enhancing system reliability and ease of maintenance while ensuring safe operation.

-

09.

Automation and Smart Features

The STON Panel Bender integrates an automatic loading and unloading system that seamlessly connects with robotic arms and other auxiliary equipment. It features intelligent bending path planning and automatic detection and adjustment functions, significantly reducing manual operations, improving production efficiency, and enhancing bending accuracy, making it ideal for high-volume production.

-

010.

Cooling System

The STON Panel Bender is equipped with an efficient cooling system, utilizing air conditioning to maintain temperature control during high-intensity operations, thereby extending the equipment’s service life.