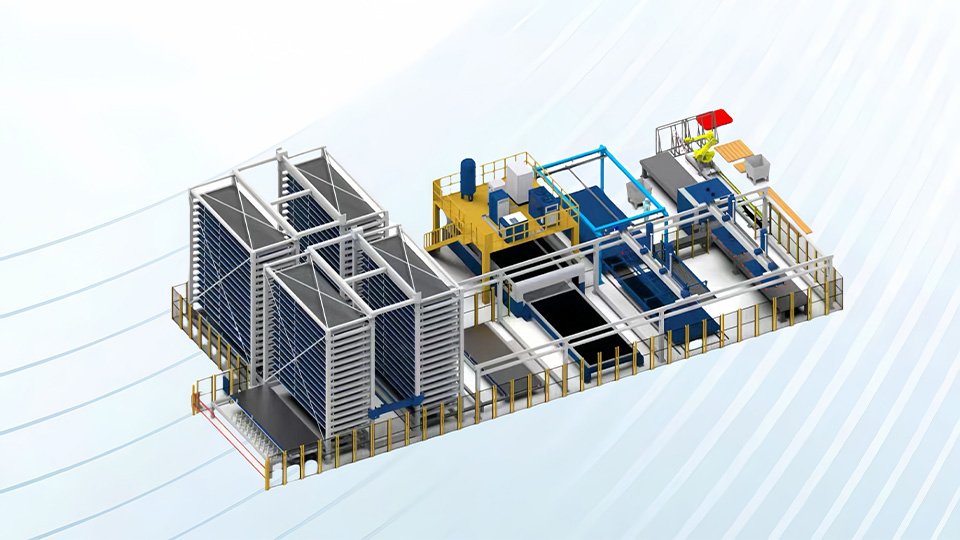

Sheet Metal Production Line

STON’s sheet metal production line offers an all-in-one solution, integrating uncoiling, leveling, cutting, punching, bending, and welding into one efficient system. This production line covers every stage of sheet metal processing, meeting the demands of high-efficiency, large-scale production.

Inquiry Now

add to cart

··· Sheet Metal Production Line ···

Customizable

Overview

STON’s sheet metal production line offers an all-in-one solution, integrating uncoiling, leveling, cutting, punching, bending, and welding into one efficient system. This production line covers every stage of sheet metal processing, meeting the demands of high-efficiency, large-scale production.

Learn more

··· check your industry match ···

Component Introduction

-

01.

Uncoiling and Leveling Module

Automates uncoiling and leveling of various coil sizes and thicknesses. The high-torque system ensures consistent material flatness with integrated tension control to prevent deformation during high-speed operations.

-

02.

Cutting and Punching Module

CNC-controlled for precise cutting and punching. Multi-tool turrets and automatic tool change minimize downtime, supporting complex shapes and fast cycle times.

-

03.

Bending and Forming Module

CNC press brakes with servo-controlled axes for high-precision bending, supporting multi-stage processes. Real-time monitoring ensures accuracy even in high-volume production.

-

04.

Welding and Assembly Module

Automated laser welding with robotic arms for spot, seam, and full penetration welding. Real-time monitoring ensures weld quality meets standards.

-

05.

Material Handling and Automation Module

Robotic arms and gantry loaders automate material transfer between stations. Vacuum and magnetic lifters handle various sizes and weights with precise positioning.