Servo CNC Punch Press

· Broad Application: Versatile in handling various sheet metal processing needs, adaptable to complex requirements.

· Automation and Customization: Multi-station turret supports customized configurations to meet diverse client needs with a high level of automation.

Inquiry Now

add to cart

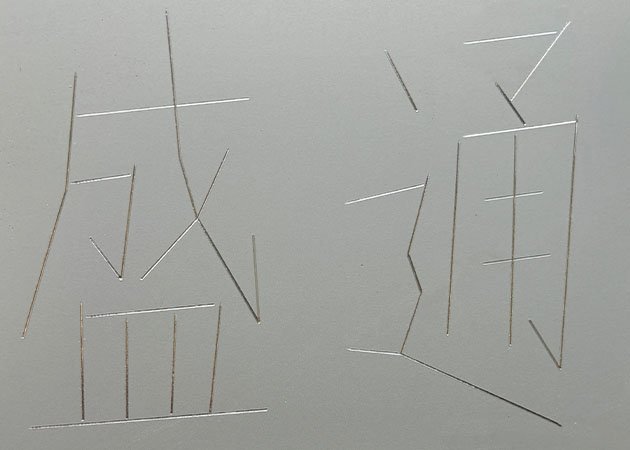

··· STON Servo CNC Turret Punch Press ···

Model: STSK-SF25/STSK-SF30/STSK-SF40

Punching Force:25/30/40tons

| Parameter | Unit | Remarks | ||||||

| Model | STSK-SF25/STSK-SF30/STSK-SF40 | |||||||

| Punching Force | 250(25)/300(30)/400(40) | KN(T) | ||||||

| Frame Structure | O-Type Closed Frame | |||||||

| Max Sheet Size for Single Positioning | X-Axis2500 Y-Axis1250/1500/2000/2500 | mm | Customizable to Non-Standard | |||||

| Max Sheet Thickness | 6 | mm | Based on Sheet Type | |||||

| Max Punching Diameter in a Single Stroke | φ88.9 | mm | Customizable to Non-Standard | |||||

| Max Punching Frequency | 1800 | hpm | ||||||

| Max Punching Hits | 800 | hpm | ||||||

| Number of Control Axes | 5(X、Y、T、C、R) | piece | ||||||

| Die Type | Long Guide 85 Series International Standard Die | |||||||

| Turret Station Distribution | 16A、11B、3C、2D(Including Rotary Stations1B、1C) | Standard | Customizable to Non-Standard | |||||

| Repositioning Cylinder | 2 | set | ||||||

| Number of Clamps | 3 | piece | ||||||

| Max Feeding Speed | X-Axis90 Y-Axis80 | m/min | ||||||

| Worktable Structure | Brush and Universal Ball Composite Work Surface | |||||||

| Max Turret Speed | 40 | rpm | ||||||

| Processing Precision | ±0.1 | mm | ||||||

| Max Load Capacity | 150 | Kg | ||||||

| Total Power Consumption | 5 | Kw | ||||||

| Air Source Pressure | 0.55 | Mpa | ||||||

| Power Supply | 380±5% | V | ||||||

| Overall Dimensions | 5000/5500/6500/7800×5200×2100 | mm | ||||||

Overview

•Broad Application: Versatile in handling various sheet metal processing needs, adaptable to complex requirements.

•Automation and Customization: Multi-station turret supports customized configurations to meet diverse client needs with a high level of automation.

•Efficiency and Precision: Fast punching speed and high accuracy ensure smooth, efficient production with minimal errors.

•Energy Efficiency: The servo-driven system reduces energy consumption, optimizes processes, minimizes material waste, and enhances resource efficiency.

Learn more

Punching Demonstrations

Industry Applieation Cases

-

Furniture Side Panel

Furniture Side Panelwatch the process

-

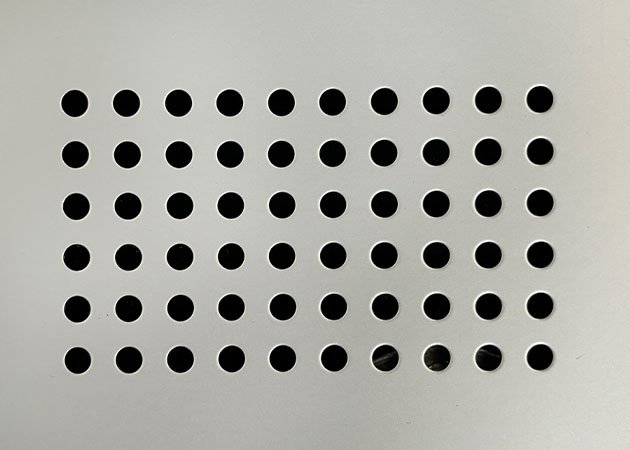

Patterned Curtain Wall

Patterned Curtain Wallwatch the process

-

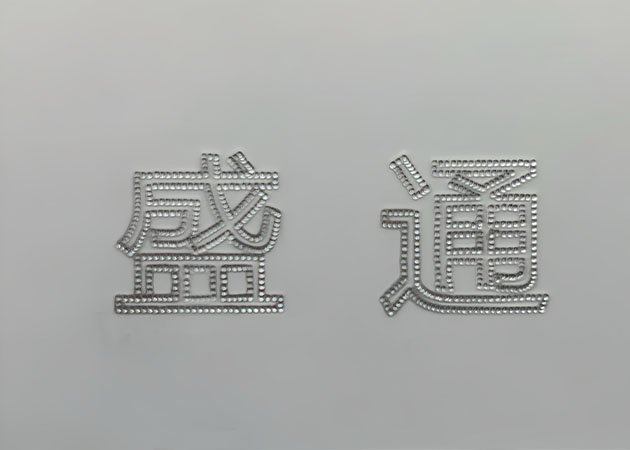

STON Sample

STON Samplewatch the process

-

Medical equipment

Medical equipmentwatch the process

Case Show

-

AC Unit Enclosure

AC Unit Enclosure -

BBQ grill

BBQ grill -

Building curtain wall

Building curtain wall -

Highway Sound Barrier

Highway Sound Barrier -

Air conditioner

Air conditioner -

Aluminum Cladding Panel

Aluminum Cladding Panel -

Cabinet Enclosure

Cabinet Enclosure -

Filing cabinet

Filing cabinet

··· check your industry match ···

Component Introduction

-

01.

CNC System

•Stable Communication and Control: Imported motherboard and Panasonic RTEX bus servo unit, utilizing a full-closed loop transmission, ensuring precise, fast control signals with minimized signal loss.

•Efficient Data Transmission: RTEX bus enables seamless data exchange and real-time monitoring with strong anti-interference capabilities.

•Upgradability and Compatibility: Supports software upgrades and is compatible with various loading/unloading systems, ensuring flexibility for future business expansion.

-

02.

Programming System

•User-Friendly: Graphical display of processing programs reduces errors, compatible with G-code, CAD, and CNCKad systems, supporting multi-axis linkage for enhanced flexibility and efficiency.

•Parameter Management: Automatically matches and stores parameters for easy recovery, significantly improving operational efficiency.

-

03.

Frame Structure

•High-Strength Design: The “O”-type closed structure, analyzed using finite element methods, ensures high stability and vibration resistance.

•Precision Machining: High-temperature annealing eliminates internal stress, and key components such as guide rails and lead screws are machined in one fixture, ensuring assembly accuracy.

-

04.

Punching Assembly

•Efficient and Stable: Proprietary sealed punching assembly prevents leaks and is equipped with a high-power servo direct drive motor, improving punching response speed.

•Smart Adjustment: The swing punching control automatically adjusts swing angles based on the process, enhancing punching efficiency. The oil-cooling system ensures stable operation under extreme conditions.

-

05.

Transmission Mechanism

•High Precision and Stability: The turret undergoes rigorous testing to ensure flatness, concentricity, and parallelism. Dual-chain transmission enhances stability.

•Precise Positioning: Upgraded cylinder positioning design reduces turret side sleeve wear, and the worm gear transmission system provides fast, precise, and quiet performance with high durability.

-

06.

Feeding System

•High-Precision Feeding: Integrated X and Y-axis guide rails and lead screws ensure precise feeding. Pneumatic clamps are easy to operate and provide stable gripping and feeding.

•Lubrication System: Multi-point automatic lubrication ensures full lubrication of all moving parts, reducing wear.